The first standard shipping container was invented and patented by Malcolm McLean (USA, 1956). Although he wasn’t an ocean shipper, he owned the largest trucking company in the country at that time. Gradually, he came up with idea of how to make intermodal transportation seamless and efficient. For years, when Malcolm started his trucking company, cargo was loaded and unloaded in odd sized wooden cases, he watched dock loaders unloading freight from trucks and transferring it to ships, and was amazed by the inadequacy of this method. He knew that both trucking carriers and shipping companies would gain from a standardized process of cargo transfer. So, Malcolm decided to make a change – he purchased Pan Atlantic Tanker Company with all its shipping assets. With it, he started experimenting with better ways of loading and unloading trucks. And finally came up with what is now called a shipping container. It’s strong, theft resistant, reliable and easy to transfer. In April 1956, the first container shipped, the Ideal X. It departed from Port Newark and successfully made its route to Houston.

Standard containers made a true revolution in freight transportation and changed international trade in many ways:

- Cargo went on a journey sealed and safe, this reduced pilfering and damage on all stages of conveyance;

- Containers have reduced labor required for loading and unloading and dramatically changed the character of port cities worldwide. Cranes substitute for man, and ports have changed to accommodate larger ships and loading facilities;

- Innovation has reduced the expense of international trade and increased its speed by greatly shortening shipping time.

By the end of the century, container shipping was transporting approximately 90% of the world’s cargo. Containerization shaped the world we live in; it provides an opportunity of fast and safe delivery of millions of goods, each day. Undoubtedly, this invention influenced globalization and world economy.

History

Before containerization, goods were usually handled manually as break bulk cargo. Typically, goods would be loaded onto a vehicle from the factory and taken to a port warehouse where they would be offloaded and stored awaiting the next vessel. When the vessel arrived, they would be moved to the side of the ship along with other cargo to be lowered or carried into the hold and packed by dock workers. The ship might call at several other ports before off-loading a given consignment of cargo. Each port visit would delay the delivery of other cargo. Delivered cargo might then have been offloaded into another warehouse before being picked up and delivered to its destination. Multiple handling and delays made transport costly, time consuming and unreliable.

Containerization has its origins in early coal mining regions in England beginning in the late 18th century. In 1766 James Brindley designed the box boat ‘Starvationer’ with 10 wooden containers, to transport coal from Worsley Delph (quarry) to Manchester by Bridgewater Canal. In 1795, Benjamin Outram opened the Little Eaton Gangway, upon which coal was carried in wagons built at his Butterley Ironwork. The horse-drawn wheeled wagons on the gangway took the form of containers, which, loaded with coal, could be transshipped from canal barges on the Derby Canal, which Outram had also promoted.[4]

By the 1830s, railroads on several continents were carrying containers that could be transferred to other modes of transport. The Liverpool and Manchester Railway in the United Kingdom was one of these. “Simple rectangular timber boxes, four to a wagon, they were used to convey coal from the Lancashire collieries to Liverpool, where they were transferred to horse-drawn carts by crane.”[5] Originally used for moving coal on and off barges, “loose boxes” were used to containerize coal from the late 1780s, at places like the Bridgewater Canal. By the 1840s, iron boxes were in use as well as wooden ones. The early 1900s saw the adoption of closed container boxes designed for movement between road and rail.

Twentieth century

On 17 May 1917, Benjamin Franklin Fitch inaugurated exploitation of an experimental installation for transfer of the containers called demountable bodies based on his own design in Cincinnati, Ohio in US. Later in 1919, his system was extended to over 200 containers serving 21 railway stations with 14 freight trucks.

Prior to the Second World War, many European countries independently developed container systems.

In 1919, Stanisław Rodowicz, an engineer, developed the first draft of the container system in Poland. In 1920, he built a prototype of the biaxial wagon. The Polish-Bolshevik War stopped development of the container system in Poland.

The US Post Office contracted with the New York Central Railroad to move mail via containers in May 1921. In 1930, the Chicago & Northwestern Railroad began shipping containers between Chicago and Milwaukee. However, their efforts ended in the spring of 1931 when the Interstate Commerce Commission wouldn’t allow the use of a flat rate for the containers.

In 1931, in USA Benjamin Franklin Fitch designed the two largest and heaviest containers in existence anywhere at the time. One measured 17’6″ by 8’0″ by 8’0″ with a capacity of 30,000 pounds in 890 cubic feet, and a second measured 20’0″ by 8’0″ by 8’0″, with a capacity of 50,000 pounds in 1,000 cubic feet.

In November 1932 in Enola, PA the first container terminal in the world was opened by The Pennsylvania Railroad Company. The Fitch hooking system was used for reloading of the containers.

The development of containerization was created in Europe and the US as a way to revitalize rail companies after the Wall Street Crash of 1929, which had caused economic collapse and reduction in use of all modes of transport.

In 1933 in Europe under the auspices of the International Chamber of Commerce the International Container Bureau (French: Bureau International des Conteneurs, B.I.C.) was established. In June 1933, the B.I.C. decided on obligatory parameters for containers used in international traffic. Containers handled by means of lifting gear, such as cranes, overhead conveyors, etc. for traveling elevators (group I containers), constructed after July 1, 1933. Obligatory Regulations:

- Clause 1.—Containers are, as regards form, either of the closed or the open type, and, as regards capacity, either of the heavy or the light type.

- Clause 2.—The loading capacity of containers must be such that their total weight (load, plus tare) is: 5 metric tons for containers of the heavy type; 2.5 metric tons for containers of the light type; a tolerance of 5 percent excess on the total weight is allowable under the same conditions as for wagon loads.[8]

Shipping containers have transformed the logistics industry over the last decades! There are more than 20 million containers around the world, and the world container fleet is growing by 3.9% every year. Not only do containers keep the cargo safe, but they have also increased the cargo capacity extensively.

The ISO has standardized the manufacture of shipping containers to make it suitable for international shipping. The standards include classification, dimensions and ratings. As a result of standardisation, we have 20-feet and 40-feet containers along with other standard varieties.

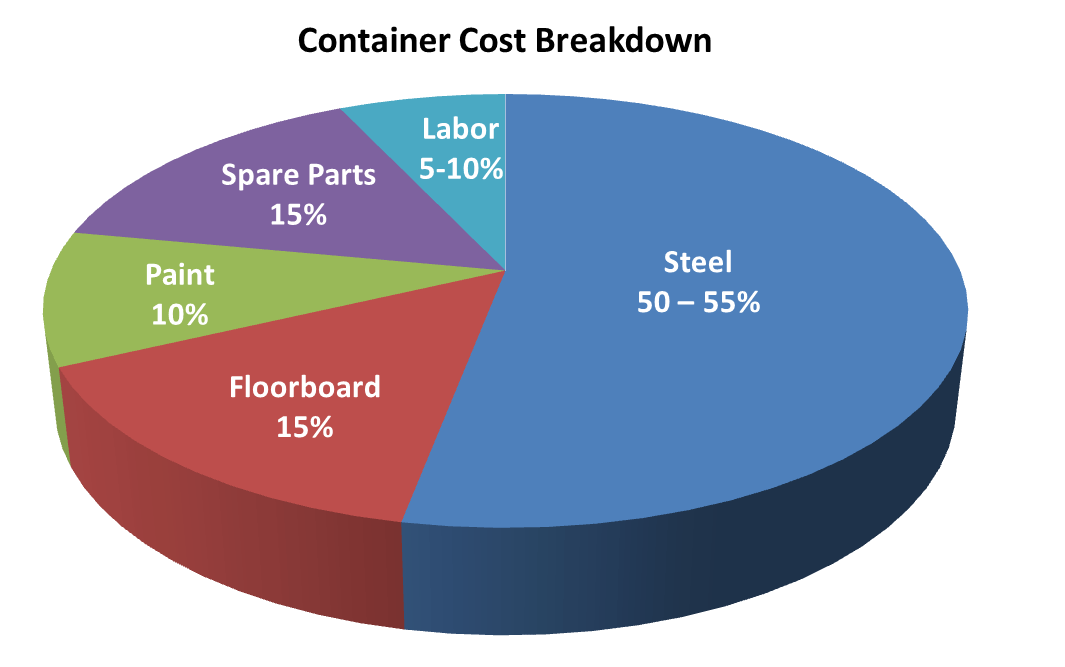

The three most common raw materials that container manufacturers are steel, flooring and paint.

Steel: In the last couple of decades, mild steel and Corten steel were used. But these days, Corten Steel dominates the industry because of its corrosion-resistant quality. It is also known as the “weathering steel”. When exposed to air and water, it oxidises and prevents corrosion.

Flooring: Earlier, oak was used in flooring. But today, hardwood plywood is used for the flooring. Oak trees take a long time to grow and are therefore not a conventional option. Bamboo grows relatively fast and is a futuristic option.

Paint: The choice of paint is important as it influences the ageing and rusting. The quality of the paint has improved a lot. Three things to take care of here is the thickness of paint, the ZINC rich primer which prevents corrosion and the undercoating of the container.

Before the first types of containers appeared, freight was handled manually as break bulk cargo. Goods were taken through a series of pick-ups and loads from factory to vessel, then from vessel to warehouse, from warehouse to another vessel and so on. This method required a lot of handling and delays, which was costly, time consuming and unreliable. Modern shipping containers were first used for combined rail and horse-drawn transport in Britain at the end of the 18th century. By the 1830s, railroads were carrying containers that were suitable for other transport modes. The U.S. Army used standard-sized small containers during WWII, which helped in faster distribution of supplies.

Interesting facts:

- the first TEU container ship was the Japanese de:Hakone Maru from shipowner NYK, who started sailing in 1968 and could carry 752 TEU containers.

- With a DWT (deadweight tonnage) of 191,317 metric tons, the OOCL Hong Kong has a cargo capacity of 21,413 TEU, making it the world’s largest container ship. The latter is an important statistic to note, as it is the TEU that determines title honours, not its length or beam

References:

- https://www.plslogistics.com/blog/the-history-of-containers/

- https://en.wikipedia.org/wiki/Containerization

- https://container-xchange.com/blog/biggest-container-manufacturers-of-the-world/